-

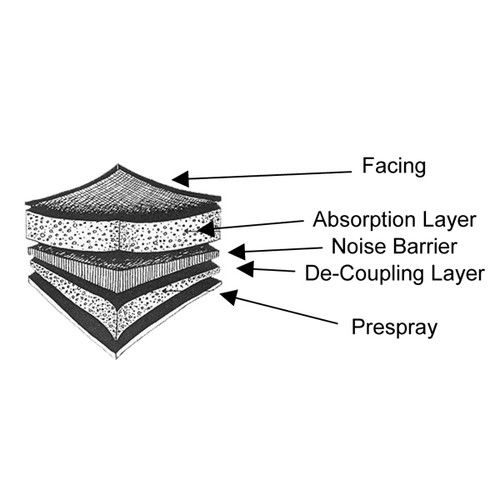

Sheet Insulation

Noise absorption layer. Hydrolysis resistant, polyether polyurethane foam. Specialized fire retarders built in to the foam. Use with Aluminium Foil Tape. Part numberDescriptionLengthWidth SAW-AM24BF4 Sheet Insulation 230cm x 140cm x...

-

ATL Composites

TECHNIREZ R1300 Flowcoat Resin

TECHNIREZ™ R1300 is a solvent free, epoxy resin specifically formulated for flow-coating. Use with TECHNIREZ™ H1300 hardener in a ratio of 100 parts resin to 50 parts hardener. TECHNIREZ will cure at room temperature and offers a one coat...

-

ATL Composites

Techniglue R60 Resin & Hardener Kit

These Techniglue R60 kits consist of a Techniglue Resin and a matching Techniglue Fast Hardener, and come in two convenient pack sizes. Techniglue R60 is a high-strength adhesive suitable for bonding structural elements fabricated from timber,...

-

ATL Composites

Rapid Cure R90 - 250ml Kit

RAPID CURE R90 250ML consisting of a 125ml resin and 125ml hardener. Specifically formulated for use with H90 to provide thin film or glue joint gelation in approximately four minutes at 25C. Used in marine joinery and repair, commercial joinery,...

-

WEST System

WEST System 501 - White Pigment

Pigments are epoxy-based pastes used to tint the epoxy mixture and provide an even colour base, or to highlight surface flaws and imperfections, prior to the final finish system. WEST System 501 white pigment comes in three sizes. Part...

-

WEST System

Gougeon Brothers on Boat Construction

The Gougeon Brothers On Boat Construction. The inventors or WEST System Epoxy give some boat building advice in this informative book. Part number SAW-321150

-

WEST System

WEST System G/Flex 650 Epoxy Resin

G/flex 650 is a toughened epoxy adhesive that is simple to use, viscous enough not to drain out of a joint, and is resilient enough to absorb the stress of expansion, contraction, shock and vibration. This GFlex resin is mixed 1:1 with GFlex Hardener...

-

WEST System

WEST System Dispensing Pumps

WEST System dispensing pumps provide a convenient, clean and accurate way to mix epoxy resin and hardeners in the correct ratio. The mixing pumps can also be a great time-saver if you are going to be mixing epoxy often. Each pump kit consists of...

-

Aquabuff 1000-W Cutting Compound (7.5 litres)

Aqua Buff 1000-W is a compound designed to remove heavy oxidation or light sanding scratches. Less aggressive than Aqua Buff 1000-F, Aqua Buff 1000-W is a great fit for buffing on soft products like the Duratec primers. Aqua Buff 1000-W is a...

-

WEST System

WEST System Roller Covers (Pair)

WEST SYSTEM FOAM ROLLER COVERS. Sold in Pairs Part numberLength SAW-321132 180mm

-

WEST System

WEST System 423 Graphite Powder

WEST SYSTEM's 423 Graphite Powder is a fine black powder that can be mixed with WEST SYSTEM epoxy to produce a low friction coating with increased scuff resistance and durability. Often used as a low-load, low-speed bearing surface, and as a coating on...

-

WEST System

WEST System 411 Microspheres

WEST System 411 Microsphere Blend is a low density filler which cures to a lightweight filling putty with excellent filling characteristics. Also used as a low density adhesive for edge gluing in strip plank construction. Mix with WEST System Epoxy to...

-

WEST System

WEST System 410 Microlight Blend

WEST SYSTEM 410 MICROLIGHT is the ideal low-density filler for creating a light, easily-worked fairing compound especially suited for cosmetic or surface applications like shaping, filling or fairing. Mixes with WEST System epoxy resin to a very smooth...

-

WEST System

WEST System 413 Microfibre Blend

WEST System 413 (previously know as 403) is a high density filler used to create a multi-purpose, high strength adhesive for structural applications like bonding, filleting and hardware bonding. Use 413 in conjunction with mixed WEST System epoxy to...

-

Zinc Tear Drop Anodes Bolt-On

Tear-drop shaped zinc anodes o suit commercial & pleasure craft where streamlining is required. Two holes for bolting on. Part numberWeightHoles(A)(B)(C)(D)Hole DiameterShape SAW-21148A 0.2kg 2 90mm 38mm 18mm 32mm 6mm Tear...

-

Zinc Tear Drop Anode With Stud

To suit commercial & pleasure craft, where streamlining is required. Part numberDescriptionLengthWidth SAW-21128A Bertram 155 X 120 X 60 W- ss Stud 155mm 120mm

-

Zinc Shaft Anodes - Silver

Round zinc anodes to suit propeller shafts to suit a range of prop shaft diameters. Assembled with socket hexagonal head cap screws. Part numberWeightInternal Diameter (A)Outside Diameter (B)Length (C) SAW-21155 0.47kg 25.40mm...

-

Zinc Heavy Duty Shaft Anodes

Zinc Heavy Duty Shaft Anodes To suit propeller shafts. Assembled with Socket Head Cap Screws. Part numberWeightShaft Size (A)Shaft Width (B)Overall Width (C) SAW-21159HD 4.6kg 2" 103mm 120mm SAW-21190 4.3kg 2-1/4" 107...

-

Zinc Rudder Anodes - Round (Pair)

Round rudder anodes in a range of diameters. Note that the brand supplied may be from Cathodic Anodes Australasia or Martyr. If this is important to you please call us and check. Sold in pairs. Part numberDiameterWeightShapeWidth (A)Height...

-

Zinc Pot Anode

Zinc anode designed to suit lobster, cray and crab pots. Part numberDescriptionWeightShape SAW-21139 125 X 38 X 25 Pot Anode 0.8kg Rectangle

Boat Building & Maintenance

Boat building and maintenance is a broad field that encompasses the design, construction, and repair of boats. It can be a challenging and rewarding hobby or profession, and it requires a wide range of skills, including carpentry, welding, metalworking, fiberglassing, and painting.

The process of boat building typically begins with the design phase. The designer will create a set of plans that specify the boat's dimensions, materials, and construction methods. Once the plans are complete, the boat can be constructed. The construction process can vary depending on the type of boat being built, but it typically involves the following steps:

- Fabrication: The boat's hull and other major components are fabricated. This may involve cutting, bending, and welding metal, or shaping and joining wood.

- Assembly: The fabricated components are assembled into the boat's hull. This may involve using screws, bolts, or rivets.

- Finishing: The boat is finished by painting, varnishing, or applying other protective coatings.

Once the boat is built, it will need to be maintained on a regular basis. This includes tasks such as cleaning, waxing, and repairing any damage. Maintenance can be a time-consuming and challenging process, but it is essential to keep the boat in good condition.

Here are some of the most common tasks involved in boat maintenance:

- Cleaning: The boat's hull should be cleaned regularly to remove dirt, algae, and other debris. This can be done with a mild detergent and water.

- Waxing: The boat's hull should be waxed regularly to protect it from the sun, water, and salt. This will help to keep the hull looking good and prevent it from rotting.

- Inspecting: The boat should be inspected regularly for any signs of damage. This includes checking the hull for cracks or leaks, the deck for loose or damaged planks, and the engine for leaks or other problems.

- Repairing: Any damage that is found should be repaired as soon as possible. This will help to prevent the problem from getting worse and causing further damage.

Boat building and maintenance can be a rewarding hobby or profession. It is a challenging but satisfying way to spend your time, and it can be a great way to learn new skills. If you are interested in learning more about boat building or maintenance, there are many resources available online and in libraries. You can also find classes and workshops offered by local boatyards and community colleges.