From Scandinavian Seat Suspension Systems (aka "4S"), this high quality XH-Series adjustable height boat seat suspension pedestal is manufactured to the highest standards. Used in coastal patrol & military applications around the world, 4S seat suspension solutions are the now available in Australia for the first time.

All 4S Seat Suspension Systems can be optionally installed on a 4S pedestal plinth to obtain the correct height for a given vessel. A foot rest that mounts to the plinth is also available. Both items are sold separately.

FEATURES OF THE XH SERIES

- Easily adjustable suspension pre‐load range of 50kg to 130kg (110‐285lb) including seat's weight.

- Height adjustment has 4 positions.

- Heavy Duty shock mitigation pedestal.

- Designed for boats travelling at up 50 knots.

- Manufactured from 6mm & 8mm Marine Grade aluminium.

- All settings are reached while sitting in the seat.

- Slide handle can be positioned on either side of the unit, decided at assembly.

- Meets ABYC H‐31 standards for type AO.

MATERIALS

As you would expect, only the best materials are used in the manufacture of 4S suspension seat systems.

Marine grade aluminium (6061T6 and 5052h32) is used for the main structural components. This alloy is designed for salt-water sensitive applications where good corrosion resistance is needed. The surface is electro powder-coated using AkzoNobel’s Interpon D2525 - a proven high-grade ‘coastal architectural’ product which is UV-resistant and suitable for use in a wide variety of conditions, environments and climates (from cold to hot, dry to humid).

Some processed aluminium parts are anodized natural/silver in +30µm.

Components such as adjustment wheels, levers, slides, rods, bolts, screws, nuts, and fasteners are all made of stainless steel AISI/SUS 316/316L.

Working plastic parts are made of POM (Polyoxymethylene) or 30% glass fibre reinforced Polyamid6.6.

High Quality Materials & Manufacture

SUSPENSION MECHANISM

Spring rates are easily adjusted through a range of 50kg to +130kg using the large adjustment wheel on the unit.

The shock absorber is of the hydraulic type. The profile is developed together with both Kayaba and Öhlins - two of the world’s leading shock absorber researchers, developers and manufacturers. The shock absorbers have passed endurance tests which simulate 500 hours of hard driving (+6G) per year, over more than 30 years.

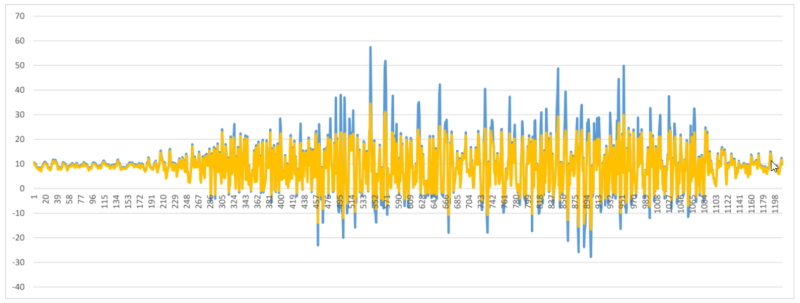

Shock Mitigation of the 4S Suspension Seat Pedestal. Fixed seat base (blue) v. 4S shock mitigation suspension seat base (yellow). Data shows 2 minutes in medium/rough conditions with impacts between 5G & 6G. Note that shock absorption efficiency increases at higher loads. Racefox® accelerometer sensors beneath seat cushions measured the forces.

Source: Swedish Institute of Computer Science

ENVIRONMENT

All parts in the 4S products are recyclable, and there are no environmentally hazardous or non recyclable materials used in the production. 4S tries to minimize the environmental foot print in every step along the process from sourcing materials locally, using the ‘greenest’ coating process available, to having 100% recycled packaging material.

| Part Number | Adjustable Height | Adjustable Height? | Sliding? | Weight | Deck Mount | Seat Mount |

|---|---|---|---|---|---|---|

| SSS-XHF246 | 320mm to 370mm | Yes | Yes - 120mm (5") slide with 5 locking positions | 14kg | 375 x 225mm (14,5x9”) | 330 x 315mm (13x12.5”) |

ASSEMBLY

- Don’t wipe off the protective grease on the shock absorber.

- Fasten the shock absorber with the rod facing upwards.

- Chose position/angle for most suitable height.

- Tighten the two(2) shock absorber screws well. The holders should squeeze hard around the shock absorber end‐collar bushings, to prevent gaps.

- The Swivel IS very tight, but mounted on deck with a chair/occupant on top – it’s all good.

INSTALLATION

- The unit can face either way – depending on preference.

- Most important is to locate the exact positions, and to choose the right fastening elements (screws) for the materials in which the product will be mounted – deck and seat.

- Use adhesive between seat base and deck to increase strength and insulate from vibrations.

- Seal drilled holes properly, to prevent water from entering.

- Don’t install seats heavier than 14kg/30lb on the seat base unit.

SETTING

- The shock absorber pre‐load has a factory setting for weights around 80‐85kg/175‐185lb.

- It normally works well for weights between 75‐95kg/165‐210lb.

- Should there be a need to adjust the pre‐load – use the accompanying hook‐key and turn the silver‐coloured adjustment ring/nut until pre‐load fits occupant.

- Moving the ring 1cm / 3/8” will change pre‐load 25kg/55lb. (One full turn = 2,5kg/5lb)

- Guide‐line: In small waves and softer sea the seat suspension should NOT move.

- The occupant can check this by lifting his/her body 3‐5cm above the seat and drop down. The seat should then compress 1‐2cm – not more – and then go back to top position.

MAINTENANCE

- Don’t use high pressure cleaners.

- Don’t lubricate plastic parts or places where it wasn’t from factory.

- Make sure there is always a protective layer of marine grease on the shock absorber end‐collar bushings, and adjustment threads.

- After every other use and/or exposure to salt water clean the seat suspension base by spraying fresh water. Leave to dry.

- Every 50 boat hours:

- Clean all surfaces with diluted detergent and a soft brush to remove sand and salt deposits. Rinse well.

- Check that screws and nuts are properly tightened and the systems works well. Do a visual inspection of any cracks or deformation of the unit, especially around mounting points. If there is any major damage present, or nuts or bolts missing, do not use the unit. Contact your supplier.

- Check for oil leakage from the shock absorber. A thin layer of oil on the shaft is normal. If there is excessive oil or the oil has sprayed out, do not use the unit. Contact your supplier.